AI Applications in Modern Factories

C 2025-06-10

The integration of Artificial Intelligence (AI) into factory operations has revolutionized manufacturing, enabling unprecedented levels of efficiency, precision, and adaptability.

Brief

The integration of Artificial Intelligence (AI) into factory operations has revolutionized manufacturing, enabling unprecedented levels of efficiency, precision, and adaptability. As industries transition toward Industry 4.0, AI emerges as a cornerstone technology driving innovations across production lines, supply chains, and workforce management. Below, we explore key AI applications transforming modern factories.

Predictive Maintenance

AI-powered predictive maintenance minimizes downtime by analyzing sensor data from machinery to forecast potential failures. Machine learning algorithms process historical and real-time data (e.g., vibration, temperature) to identify anomalies, allowing factories to schedule repairs proactively. For example, Japanese SiC manufacturers reduced defect detection time by 83% using AI vision systems . This approach cuts maintenance costs by up to 25% and extends equipment lifespan .

Quality Control

AI enhances product quality through computer vision and deep learning. Automated inspection systems detect defects in real-time by analyzing images of products on assembly lines. For instance, AI-driven visual systems in semiconductor production achieve 90%+ accuracy in identifying surface flaws, reducing waste and manual inspection costs . Advanced models even adjust production parameters autonomously to correct deviations .

Automated Production Scheduling

AI optimizes resource allocation and workflow efficiency by analyzing demand forecasts, inventory levels, and machine availability. Reinforcement learning algorithms dynamically adjust schedules to prioritize urgent orders or avoid bottlenecks. A case study showed AI reducing production cycles by 15% while improving on-time delivery rates .

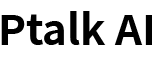

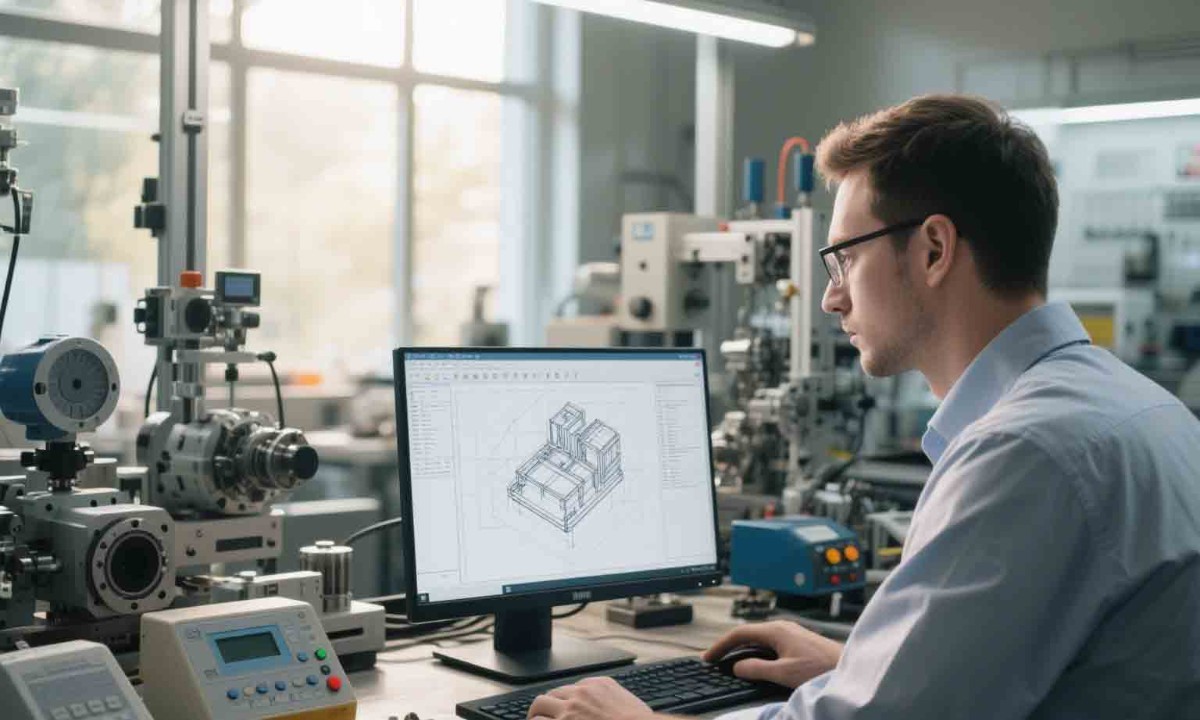

Robotics and Collaborative Robots (Cobots)

AI-driven robots handle repetitive tasks like assembly, packaging, and material handling. Cobots equipped with machine learning adapt to human workers, enhancing safety and productivity. For example, automotive factories use AI robots to perform precision welding, achieving error rates below 0.1% .Supply Chain Optimization

AI analyzes market trends, supplier performance, and logistics data to optimize inventory management and procurement. Predictive models anticipate raw material price fluctuations, enabling cost-effective purchasing strategies. Companies leveraging AI in supply chains report 20–30% reductions in logistics expenses .

Energy Efficiency Management

Smart factories employ AI to monitor and optimize energy consumption. By analyzing patterns in electricity usage, AI identifies wasteful processes and recommends adjustments, such as shifting high-energy tasks to off-peak hours. This reduces carbon footprints and operational costs by up to 18% .

Worker Safety and Ergonomics

AI systems monitor employee movements through cameras and wearable sensors, flagging unsafe postures or fatigue. For example, posture analysis algorithms in assembly lines reduce workplace injuries by 40% . Real-time alerts ensure compliance with safety protocols, fostering healthier work environments .

Challenges and Considerations

While AI offers transformative benefits, challenges persist:Data Security: Sensitive production data risks breaches, necessitating robust encryption and access controls .

Technical Maturity: AI models may struggle with rapid environmental changes, requiring continuous retraining .

Skill Gaps: A shortage of AI-literate technicians delays implementation .

Future Outlook Emerging technologies like edge computing and 5G will enhance AI's real-time capabilities, while quantum computing could unlock breakthroughs in material science and process simulation . As factories adopt AI at scale, the focus will shift toward ethical AI governance and cross-industry collaboration to standardize data-sharing frameworks.