Tesla: Revolutionizing Manufacturing with AI-Driven Innovation in 2025

C 2025-05-28

In 2025, Tesla stands as a global leader in integrating artificial intelligence (AI) into its production processes, transforming automotive manufacturing through cutting-edge technologies and relentless innovation.

In 2025, Tesla stands as a global leader in integrating artificial intelligence (AI) into its production processes, transforming automotive manufacturing through cutting-edge technologies and relentless innovation. From autonomous robotics to predictive analytics, Tesla’s AI applications have redefined efficiency, quality, and scalability in its factories worldwide.

The Optimus robots utilize reinforcement learning and sim-to-real training to adapt to dynamic factory conditions. For instance, their AI systems analyze millions of simulated scenarios to refine movements, ensuring precise handling of delicate components like battery modules. This approach has reduced human error in repetitive tasks by over 90%, while increasing production throughput by 15%

In 2025, Tesla’s Shanghai Gigafactory achieved a historic milestone by ramping up production of the Model Y in just 6 weeks, a feat enabled by AI-driven digital twin technology. The digital twin replicates the entire factory in a virtual environment, allowing engineers to simulate and optimize production changes in real time. This innovation reduced new model launch cycles by 60% compared to traditional methods, with the Model Y’s production 节拍 (cycle time) dropping from 76 seconds per vehicle to 37 seconds .

For quality control, Tesla employs computer vision AI with 256 high-resolution cameras to inspect every vehicle component. The system detects defects as small as 0.05mm, ensuring that only flawless parts proceed to assembly. In 2025, this technology helped Tesla achieve a 99.7% welding automation rate and a 32% reduction in production defects compared to 2022 levels.

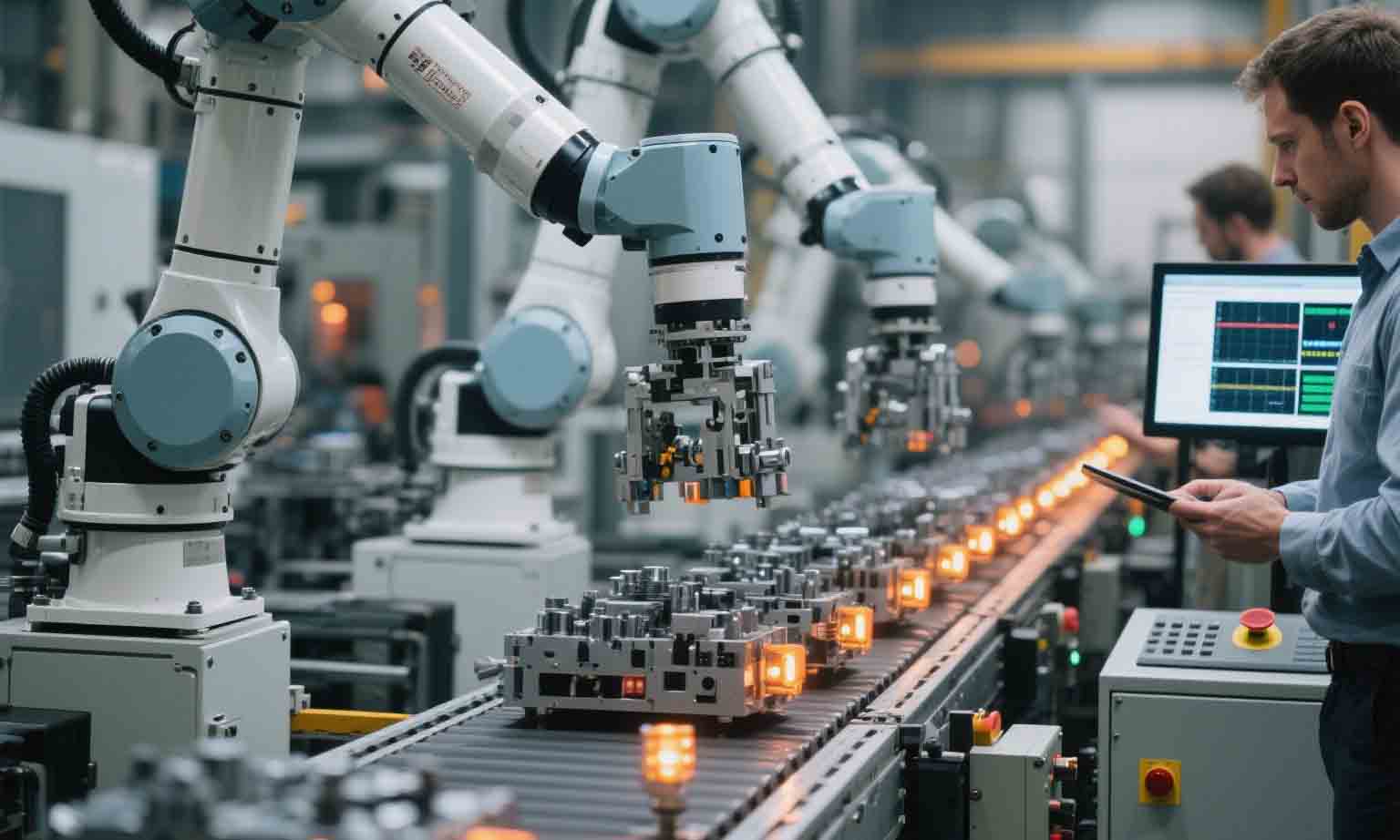

AI-Powered Robotics and Automation

Tesla’s Fremont and Gigafactory facilities now operate with Optimus humanoid robots, a groundbreaking innovation designed to handle complex tasks on the production line. Developed under Tesla’s Optimus program, these robots leverage AI algorithms to perform intricate operations such as battery cell sorting, tool handling, and equipment maintenance 25. By 2025, Tesla plans to deploy over 1,000 Optimus robots, with initial batches already demonstrating autonomous mobility and dexterity in factory environments .The Optimus robots utilize reinforcement learning and sim-to-real training to adapt to dynamic factory conditions. For instance, their AI systems analyze millions of simulated scenarios to refine movements, ensuring precise handling of delicate components like battery modules. This approach has reduced human error in repetitive tasks by over 90%, while increasing production throughput by 15%

AI-Optimized Production Lines

Tesla’s manufacturing processes are deeply integrated with AI-driven systems that optimize every stage of production. The company’s Dojo supercomputer, a custom-built AI training platform, plays a pivotal role in refining production workflows. Dojo processes vast datasets from Tesla’s global factories to identify bottlenecks, predict equipment failures, and streamline assembly sequences .

In 2025, Tesla’s Shanghai Gigafactory achieved a historic milestone by ramping up production of the Model Y in just 6 weeks, a feat enabled by AI-driven digital twin technology. The digital twin replicates the entire factory in a virtual environment, allowing engineers to simulate and optimize production changes in real time. This innovation reduced new model launch cycles by 60% compared to traditional methods, with the Model Y’s production 节拍 (cycle time) dropping from 76 seconds per vehicle to 37 seconds .

Predictive Maintenance and Quality Control

AI also powers Tesla’s predictive maintenance systems, which monitor machinery health using real-time sensor data. Machine learning models analyze vibration patterns, temperature fluctuations, and energy consumption to forecast equipment failures up to 72 hours in advance. This proactive approach has minimized downtime by 40% and reduced maintenance costs by 25% across Tesla’s facilities .

For quality control, Tesla employs computer vision AI with 256 high-resolution cameras to inspect every vehicle component. The system detects defects as small as 0.05mm, ensuring that only flawless parts proceed to assembly. In 2025, this technology helped Tesla achieve a 99.7% welding automation rate and a 32% reduction in production defects compared to 2022 levels.

Supply Chain and Logistics

Tesla’s AI applications extend beyond the factory floor to supply chain management. The company uses AI algorithms to forecast demand, optimize inventory levels, and coordinate logistics. For example, AI models analyze regional sales trends, energy prices, and raw material availability to adjust production schedules dynamically. This agility has enabled Tesla to maintain a 95% localized parts supply chain in China, reducing lead times and costs significantly.